Liquid level sensors also known as flow switches or fluid sensors are crucial devices in a wide range of industries, playing a fundamental role in liquid level measurement.

What is a Liquid Level Sensor?

A liquid level sensor is a device designed to detect the level of a liquid within a container. It can accurately determine whether the liquid is at a certain height, if it's rising or falling, or provide a continuous reading of the liquid's position. There are various types of liquid level sensors, each with its own principle of operation, such as float type sensors, ultrasonic sensors, capacitive sensors and optical sensors.

How Do They Work?

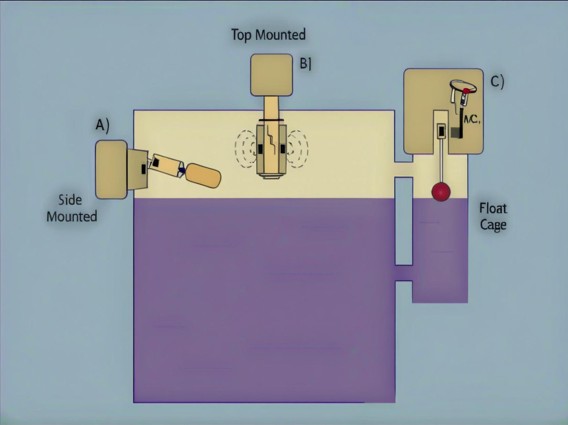

Float - type Sensors: These are one of the most basic types. A float is attached to a rod or a mechanism. As the liquid level changes, the float rises or falls. This movement can be translated into an electrical signal, for example, by using a potentiometer. When the float moves, it changes the resistance in the potentiometer circuit, and this change in resistance can be measured to determine the liquid level.

Ultrasonic Sensors: Ultrasonic liquid level sensors work by emitting ultrasonic waves towards the liquid surface. These waves travel through the air above the liquid, bounce off the liquid surface, and return to the sensor. By measuring the time it takes for the waves to travel to the liquid and back, the sensor can calculate the distance to the liquid surface. Based on the known height of the container, the liquid level can be accurately determined.

Capacitive Sensors: Capacitive liquid level sensors operate on the principle of capacitance change. The sensor consists of a probe and a reference electrode. When the liquid level around the probe changes, the dielectric constant of the material surrounding the probe changes. Since capacitance is related to the dielectric constant, this change in capacitance can be detected and correlated to the liquid level.

Optical Sensors: Optical liquid level sensors use light to detect the liquid level. Some optical sensors have a light - emitting diode (LED) and a photodetector. When the liquid level reaches the sensor, the light from the LED is refracted or absorbed differently, and the photodetector can sense this change, indicating the liquid level.

The Importance of Liquid Level Measurement

Industrial Applications

In the chemical industry, precise liquid level measurement is essential for processes such as mixing, dosing, and storage. For example, in a chemical reactor, maintaining the correct liquid level ensures that the chemical reactions occur under the right conditions. If the liquid level is too high, it could lead to over - pressurization or spillage of dangerous chemicals. If it's too low, the reaction may not proceed as expected, resulting in poor product quality.

In the oil and gas industry, liquid level sensors are used in storage tanks to monitor the amount of crude oil, refined products, or other liquids. This helps in inventory management, ensuring that there is enough product for distribution and preventing over - filling or under-filling of tanks.

Automotive and Aerospace

In the automotive field, liquid level sensors are used to monitor the coolant level in the radiator. Maintaining the proper coolant level is crucial for the engine's temperature regulation. If the coolant level drops too low, the engine can overheat, causing serious damage.

In aerospace, liquid level sensors are used to monitor fuel levels in aircraft fuel tanks. Accurate fuel level measurement is vital for flight safety and planning, as it allows pilots to determine how much fuel is available for the journey and make necessary decisions.

Domestic and Commercial Applications

In household appliances like washing machines and dishwashers, liquid level sensors ensure that the right amount of water is used for each cycle. This not only saves water but also ensures that the appliances operate efficiently and clean the dishes or clothes properly.

In commercial buildings, liquid level sensors are used in water storage tanks, sump pumps, and HVAC systems. For instance, in a sump pump system, a liquid level sensor can detect when the water level in the sump pit has risen to a certain level, triggering the pump to start and prevent flooding.

In 2024, BST worked with a USA customer for their HVAC system, the components BST provided are:

1, BF-21&BF-23 series liquid level sensor with signal transformer, due to confidentiality with customer, pictures can't shown in here.

2, Pump PCBA design with 3 inductors and 1 transformer.

In conclusion, liquid level sensors are an integral part of operations across multiple sectors. Their ability to accurately measure liquid levels ensures the safety, efficiency, and proper functioning of various processes and systems. As technology continues to evolve, we can expect even more advanced and accurate liquid level sensors to emerge, further enhancing our ability to manage liquid related tasks.

If you have any specific questions about liquid level sensors, like which type is best for a particular application, feel free to leave a comment. Also, if you've had any interesting experiences with liquid level measurement in your work or projects, we'd love to hear about them.