A Reed sensor is magnetically actuated switch widely used in proximity detection, position sensing and contactless switching applications. Unlike optical or capacitive proximity sensors, reed sensor rely on magnetic fields to trigger switching, making it ideal for harsh environments (dust, moisture, or explosive atmospheres).

A reed sensor consists of two ferromagnetic reed contacts sealed in a glass tube filled with inert gas. When exposed to a magnetic field (e.g., from a permanent magnet or electromagnet), the reeds magnetize, attract each other, and close the circuit. The sensor triggers when the magnet approaches within a predefined operating distance, typically 1–50 mm, depending on magnet strength, usually customer will ask BST to customize to fit into their design.

Reed switch: Hermetically sealed glass envelope with Ni-Fe alloy contacts.

Actuation magnet: Rare-earth (NdFeB) or ferrite magnets; selection impacts sensitivity.

Protective housing: IP67/IP69K-rated enclosures for industrial proximity sensing. Housing materials could be plastic or steel.

Operate/Release Sensitivity (AT): Magnetic field strength required for contact closure.

Voltage/Current Rating: Typically 0.5–10A, 100–500V DC.

Environmental Factors: Temperature range (-40°C to +150°C) and resistance to shock/vibration.

Form Factor: SMD vs. through-hole; shielded vs. unshielded.

A reed switch is an electrical switch operated by an applied magnetic field. Here's a detailed breakdown:

Components: Consists of two ferromagnetic, flexible metal contacts (reeds) enclosed in a hermetically sealed glass tube filled with inert gas or a vacuum.

Material: The reeds are typically made of nickel-iron alloy, which magnetizes easily.

Activation: When a magnet approaches, the reeds magnetize, attract each other, and close the circuit (for a normally open, NO switch). Removing the magnet allows the reeds to spring back, breaking contact.

Normally Open (NO): Closes under magnetic influence.

Normally Closed (NC): Opens when a magnet is near.

Changeover: Switches between two circuits.

This is the most common type. NO reed switches are off in their resting position, with an air gap between the blades (hence open). Introduction of a magnet polarises the two reeds, pushing the contacts together and completing a circuit. Thus, current is allowed to flow across the switch. When the magnetic field is moved far enough away again, the contacts return to their apart position through the natural spring force created by their flexibility.

The reeds are already in contact in their natural position, providing a closed circuit and allowing current to flow across the switch when no magnet is present. Introduction of a magnetic field with reversed polarity pushes the contacts apart, breaking the circuit.

An SPDT reed sensor is a versatile magnetic proximity switch that offers two switching positions. Unlike single-throw switches (NO or NC), it can route a signal or power to either of two circuits based on the presence or absence of a magnetic field.

It contains three terminals: a common terminal (C), a normally open terminal (NO), and a normally closed terminal (NC). Internally, two sets of reed contacts are arranged to allow switching between the two circuits.

There are also other types, such as bistable type, miniature type etc, but in this article, we will not further discuss.

Permanent Magnet Actuation: A fixed permanent magnet (e.g., NdFeB, Ferrite) moves into proximity to trigger the reed switch. The actuation distance is 1–50 mm (depends on magnet strength).

Electromagnet Actuation: An energized coil generates a magnetic field to actuate the reed switch remotely. The actuation distance is adjustable via current input.

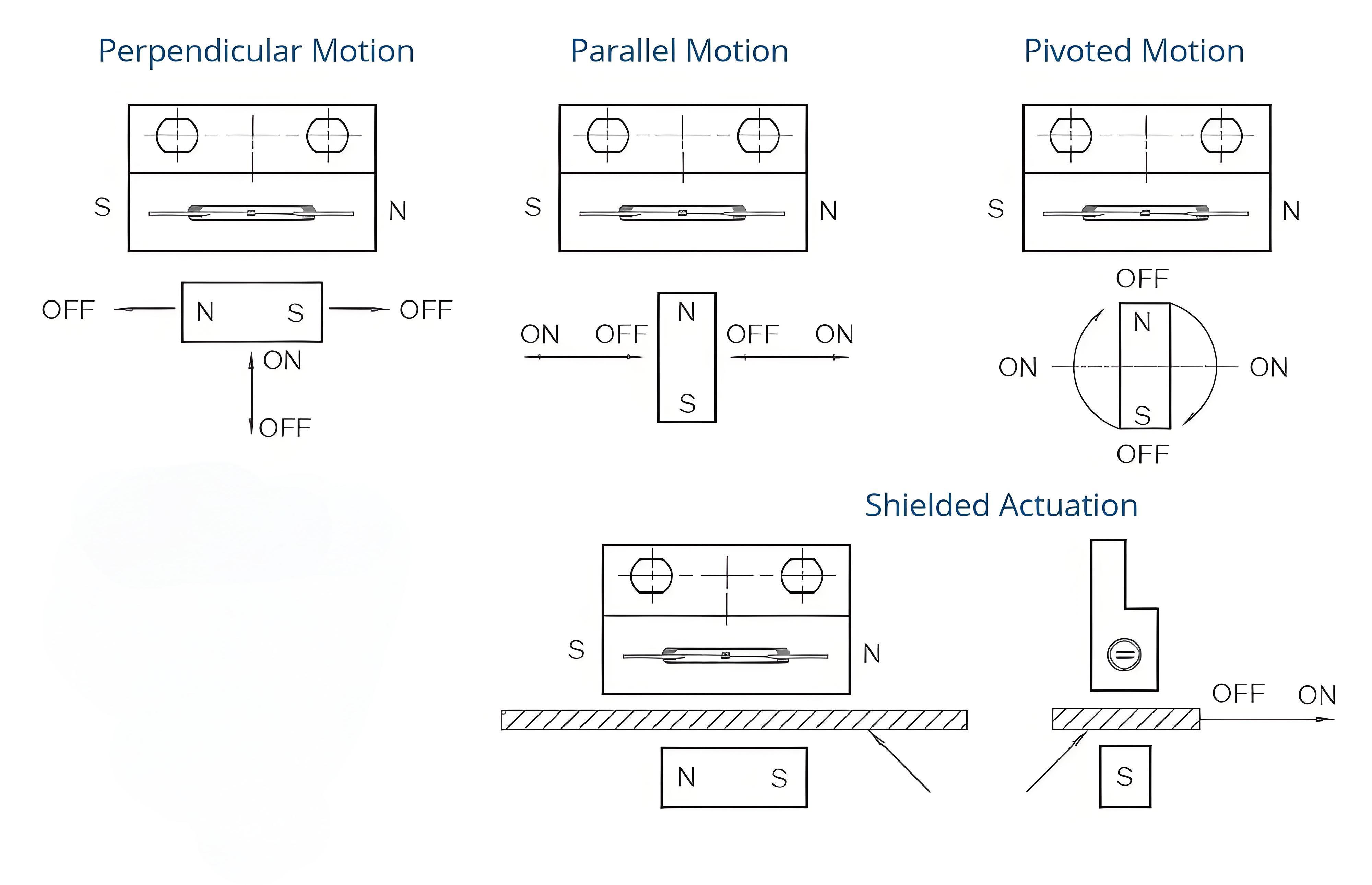

Reed sensors can be actuated not only by the presence of a magnetic field but also by its orientation. The switching behavior depends on the alignment of the magnet’s poles relative to the reed switch. Proper positioning of the magnetic field ensures reliable operation and prevents unintended actuation. Please refer to the drawing below for details.

| Parameter | Reed Sensor | Hall-Effect Sensor |

| Power Consumption | Passive (no power required) | Active (requires external power) |

| Response Time | ~0.5 ms | ~1–2 ms |

| Durability | Mechanical wear (contact erosion) | Solid-state (no moving parts) |

| Cost | Lower (simple construction) | Higher (integrated electronics) |

| EMI Resistance | Immune to EMI | Susceptible to electromagnetic noise |

Electronic Switch: Achieves circuit on/off by closing when the external magnetic field exceeds the activation value. Applied in automatic control systems, safety protection devices, etc., boasting advantages of safety, reliability, and rapid response.

Safety Device: Capable of cutting off circuits without electrode contact. Suitable for smart door locks, protective cover monitoring systems, etc. Automatically reverts to the open state after the magnetic field is removed.

Counter and Switch: Applied in devices like electronic counters. The magnetic field triggers the reed switch to close for counting pulses, meeting demands for high reliability, low power consumption, and long service life.

1. Mechanical Contact Wear: Primary Failure Mode: Erosion of reed contacts due to arcing during switching.

2 Load Type:Resistive Loads (e.g., simple on/off circuits): 1–10 million cycles. Inductive Loads (e.g., relays, motors): Reduced lifespan (100k–1M cycles) due to arcing.

3 Contact Material: Standard Reeds: Nickel-iron (Ni-Fe) alloy – 1–5 million cycles. Gold-Plated Reeds: Enhanced corrosion resistance – up to 10 million cycles.

4 Environmental Stressors: Temperature:

Extreme heat (>150°C) accelerates contact oxidation.

Humidity/Corrosion: Hermetically sealed switches (e.g., IP67-rated) outperform non-sealed in damp environments.

Vibration/Shock: Mechanical stress can misalign contacts or crack glass envelopes.

Miniaturization: Subminiature reed sensors for IoT devices.

Hybrid Solutions: Reed sensors paired with Hall-effect ICs for redundancy.

Smart Manufacturing: Integration with IoT for predictive maintenance.

Glass Envelope Stress: Thermal expansion mismatches during sealing.

Contact Bounce: Mitigated via gold-plated contacts or arc suppression circuits.

Magnet Alignment: Critical for consistent proximity detection accuracy.